The US heat treatment industry has emerged strongly after two years of COVID-19 restrictions and supply chain constraints. Despite being considered an essential industry and never being asked to suspend operations, it was still impacted by the overall performance of the rest of the economy, especially the automotive industry.

However, there has been robust growth from late 2021 and 2022 that has extended until today. Although there has been some slower growth in Canada and the US Northeast region, the growth of southern states from California to Florida has made up for the slowing heat treatment in the Northern US region.

We have seen five trends in the heat treatment industry and five new trends in heat treatment process application. One trend in the heat treatment industry is consolidation by larger corporate entities, which buy smaller privately-owned heat-treating companies or private heat treaters selling operations to private equity firms.

The aerospace and defense industries are facing fast growth with high demand for airplanes and new weapons for the Ukrainian and Israeli wars. The furnace manufacturers have record sales in 2021 and 2022, but booking in the last three months has slowed but not very noticeably. The SDG and environmental goals are less prominent in the minds of many US heat treaters.

The US heat treatment industry is mostly against government-imposed regulations. Economic efficiency and cost reduction drive technological change in the US heat treatment industry. Examples of game-changing technologies will be discussed. The Metal Heat Treatment Institute (MTI), an association of commercial heat-treatment companies in the US) is predicting an 11% slowing economy in late 2024 and 2025 and recovery in late 2026. Discussion of global issues facing the heat treatment industry and a new approach for attracting younger generations will be presented.

Total US Heat Treatment (Captive and Commercial) – $35.13 Billion

US Commercial Heat Treatment – $5.27 Billion

Number of Commercial Heat Treating Companies in the US – 605

The ratio between Captive and Commercial HT – 85%/15%

Total number of employees in Commercial HT companies – 21,000

Number of Furnace Equipment and Related Components Manufacturers – 298 companies

Total Shippment (NAICS 333994) Industrial Furnaces and Ovens – $2.8 B

Number of Employees (NAICS 333994) Industrial Furnace and Ovens – 10,405.

In Europe, the heat treatment performed in captive and commercial is 80% to 20%, while in Asia (excluding Japan), it is 90% to 10% to the best of my estimate.

The below data are particularly intriguing due to the significant difference in sales per employee. For instance, the US commercial heat-treating shops can have sales ranging from $100,000 to $280,000 per employee. (Bill Jones stated the $280,000 figure in The Monty interview in 2020.) The higher sales per employee are typically achieved by commercial heat treating companies specializing in vacuum heat treatment, vacuum brazing, nitriding, and catering to the medical, defense, and aerospace industries.

Even higher profitability may occur for companies specializing in surface modification processes such as PVD, CVD, and high-end coating. The profitability of the HIP operation depends on loading utilization and a large customer base with similar parts for processing.

Some people compare running a business to bicycling; you must paddle continuously to avoid falling. Life is never easy, but the same goes for business.

Janusz Kowalewski, Ipsen Japan, November 2023

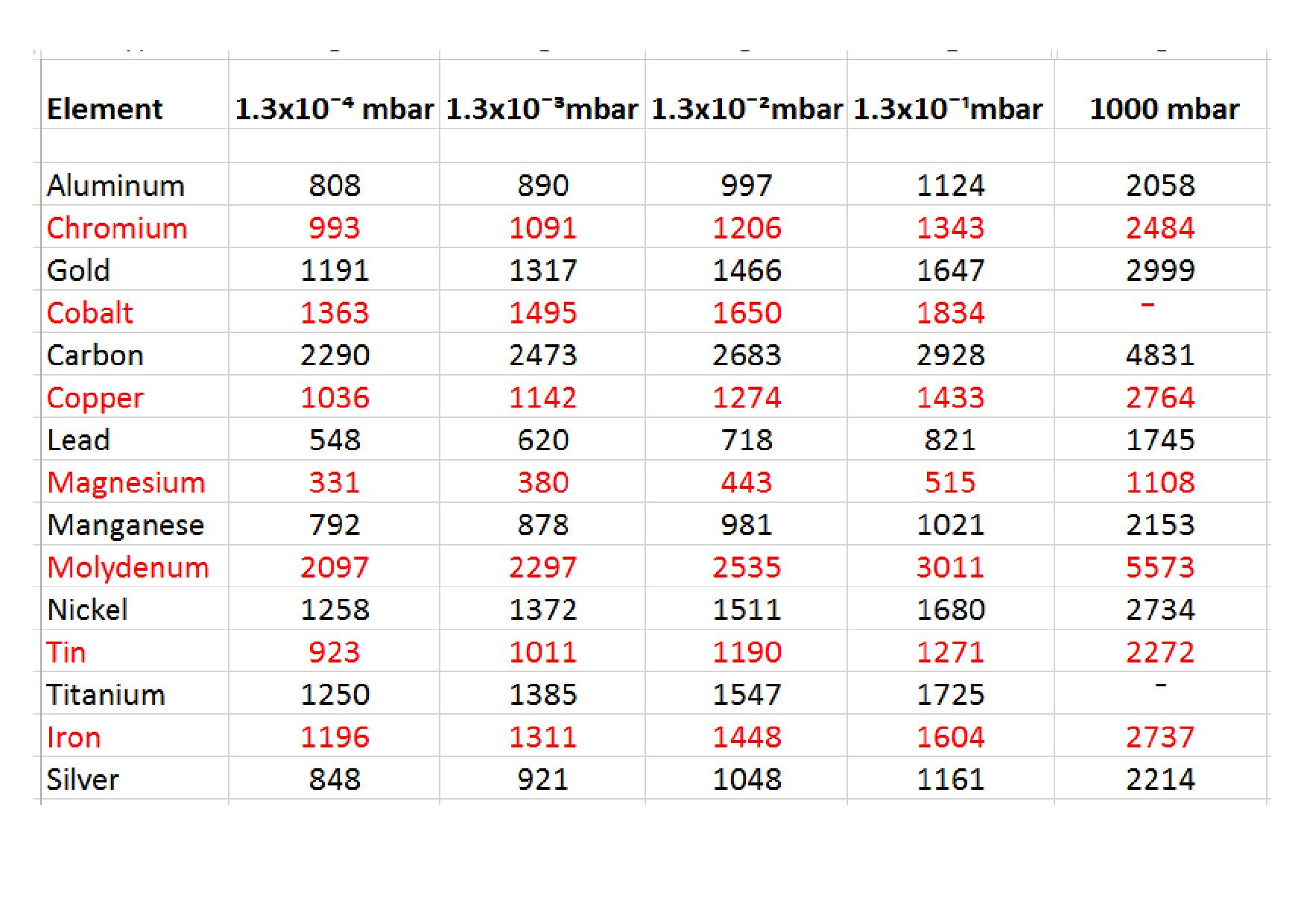

Most vacuum furnace operators rely on the partial pressure option to prevent sublimation, diffusion bonding, and alloy depletion during high-temperature, high-vacuum operation.

The partial pressure with noncombustible gases can operate up to 5 Torr (666 Pa), with the most popular setup from 500 to 1500 microns (60-200 Pa) and with Hydrogen up to 10 Torr. The partial pressure is crucial in various processes, including hardening, brazing, and sintering. Several excellent articles about partial pressure description exist on websites and in heat-treating magazines.

The use of partial pressure segments during burnout cycles has advantages over only deep vacuum setups and should be considered in routine maintenance procedures. Combining partial pressure and vacuum provides a cleaner hot zone in less time.

As per AMS 2769 3.2.4.1.1 Bake-Out Cycle guidelines, the vacuum operator must ensure that the heat-treating furnace meets the contamination requirements of the relevant heat-treating specifications. To achieve this, the operator should carry out bake-out cycles, maintaining a temperature of at least 50°F (27°C) higher than the maximum intended temperature, for not less than one hour. During the bake-out cycle, the pressure should equal or below the intended operating pressure.

The cleaning cycle with partial pressure is very straightforward.

The operation consists of opening a needle valve during partial pressure to achieve the process pressure, then closing it again when the pressure exceeds the SP.

Depending on the supply pressure and the needle valve setting, the delta on the chamber pressure can be large, small, or flat if the needle valve is set just below the SP. The intermittle gas flow gives a sweeping action, as the pumps always pull the gas from the chamber. So, any O2 or outgassing from contamination is swept from the chamber.

The greater concentration of molecules within a given volume leads to an increased frequency of collisions between the molecules and the insulation. As a result, the kinetic energy of the molecules is also higher, allowing for deeper penetration of energy into the refractory. The objective is to eliminate any impurities and thoroughly cleanse the insulation. Therefore, the approach channels energy into the refractory to facilitate its cleaning.

Once the partial pressure segment is complete, the process continues with the vacuum again. The operator should watch the chamber, foreline, and roughing pump pressures. As the vacuum segment continues, these values will drop. When values stop falling, we have removed most of the contamination.

Janusz Kowalewski, Ipsen Japan, November 2023

The Japan Heat Treatment Association has requested that I deliver a presentation on the current state of the heat treatment industry in the United States at the Yokohama IFHTSE Conference.

I have categorized the trends in the heat treatment industry into five HT Industry trends and four HT Metallurgical Process trends. What are the current trends in the heat treatment industry from your perspective? I’m interested to hear your thoughts on the accuracy of these five trends.

Commercial Heat Treatment and Furnace Industries Consolidation.

The commercial heat treatment industry in the US is undergoing consolidation and transitioning from traditional private family ownership to a more corporate style of ownership. Companies like Bodycote, Aalberts, and Thermal Process Holdings (TPH) lead this change alongside private equity firms.

The trend is confirmed by the recent sale of Stack and Lake heat treatment companies to Bodycote.The high costs of upgrading equipment, complying with environmental standards, and meeting industry requirements prove difficult for smaller private companies. Also, smaller furnace companies will need consolidation in the next economic slowdown predicted by 2024-25.

Digitalization, Simplification, and Automation of Heat Treatment Operation.

The upgrade mainly involves improving the control system to enhance convenience, recording, connectivity, accuracy, and controllability, driving the digitization of processes. The digital recording requirements specified in AMS 2750G confirms this trend. The increasing cost and shortage of labor make automation a prerequisite in many operations.

Transfer of Heat Treatment Process and Maintenance Know-How from End User to Vendor (Furnace Manufacturer) Driven by Proprietary Software.

More furnace companies offer proprietary software for maintenance supervision (e.g., PdM Metrisc) and process setting (e.g., AVAC for LPC).

Replacement of High Generating CO2 Furnaces with More.

Efficient Furnaces and Larger Furnace Sizes.

There are furnaces with improved insulation and more efficient heating systems, and vacuum furnaces are replacing smaller sealed quench furnaces.

Increasing Nano and Thermo/Chemical Surface Modification

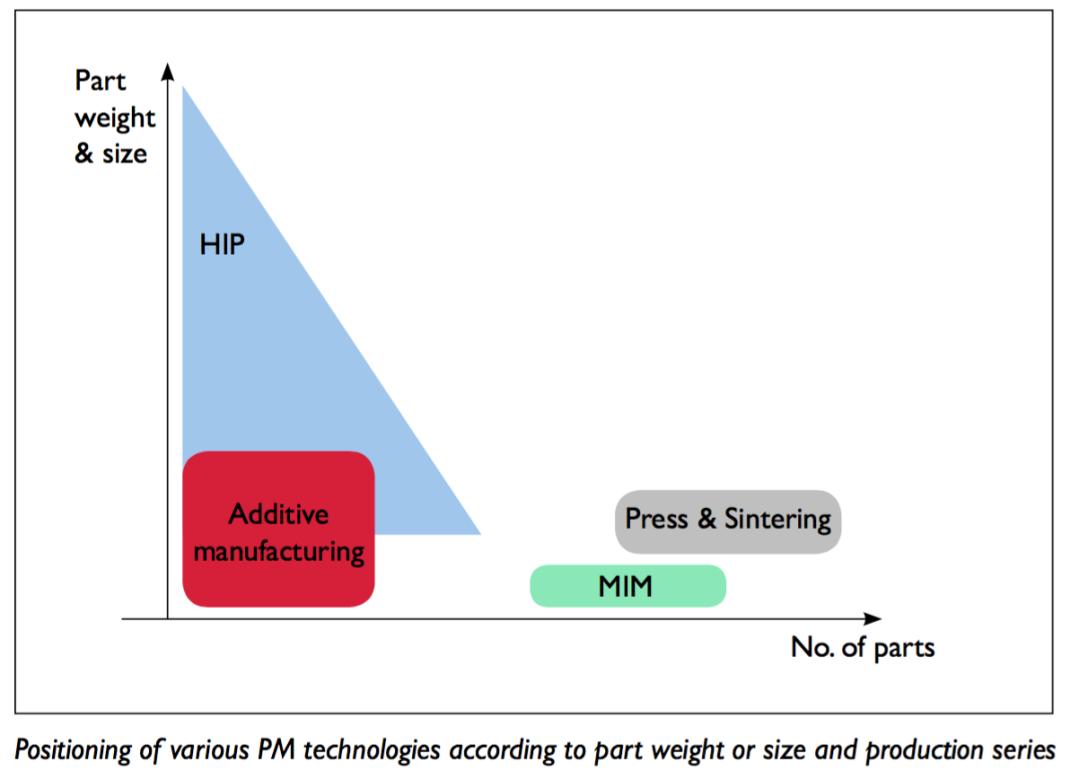

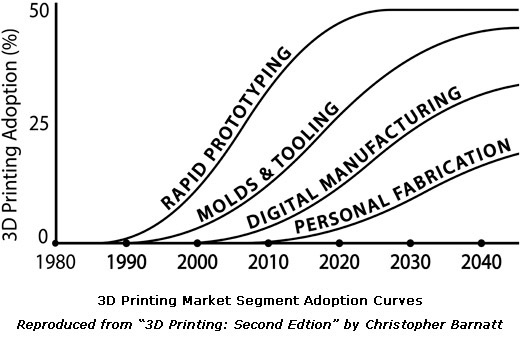

Processes for Near-Shape Technologies, MIM, and Additive Manufacturing.

The automotive industry increasingly utilizes the FNC process, while MIM and Additive Manufacturing are experiencing steady growth.

Janusz Kowalewski, Ipsen Japan, November 2023

I often receive inquiries from customers who wonder if traditional vacuum furnaces designed for Inconel and Copper brazing can also braze aluminum. Most people believe that if a vacuum furnace has a diffusion pump and can heat up to 1320C, then it should be able to handle aluminum brazing, which only requires a maximum operating temperature of 650C. However, this is not the case, and we’ve compiled a list of reasons why, as explained by Jim Grann, Ipsen’s in-house Aluminum Brazing expert:

1. Special all-metal hot zones are required for aluminum brazing.

2. Opening the door of a VAB (Vacuum Aluminum Brazing) furnace at temperatures ranging from 170C to 534C is impossible in a standard brazing furnace without damaging the hot zone.

3. Square six-sided heating is necessary for aluminum brazing.

4. The standard moly or graphite element and other hot zone components are incompatible with the VAB process.

5. The pumping systems must have faster pumping speeds for the VAB process than a standard furnace.

6. A standard furnace has cold walls, whereas a VAB has a specially designed recirculating heated water control.

7. The main valve on a VAB has special design considerations employed for dealing with magnesium.

Here are some additional points for customers performing vacuum aluminum brazing to consider:

1. Burnouts don’t remove everything but re-vaporize materials, with a small percentage pumped out. The balance of materials being pushed deeper into the shielding and onto the cold walls.

2. How much magnesium can condense on a typical cold wall furnace is surprising.

3. VAB processes seldom go above 704C for clean-up cycles.

4. A standard furnace can reach 1320C, but any leftover aluminum would surely vaporize onto the customer’s fixtures and parts in subsequent processes, which could cause melting problems and eutectic-related issues.

5. VAB elements and insulators are specifically designed to handle the magnesium generated from the VAB process.

When working with aluminum brazing vacuum furnaces, it’s crucial to take preventative measures to avoid maintenance and operational problems. Cold surfaces can attract magnesium oxide (MgO) and magnesium (Mg), which can cause short circuits between resistors and the thermal shielding of the chambers. The oxide creates stubborn deposits that are difficult to remove and still conduct electricity enough to cause short circuits. Removing magnesium deposits can also be hazardous, as magnesium ignites easily in the presence of air and can cause serious injury to operators and maintenance crew. The resulting droplets can’t be extinguished with water and burn at 2000C.

Janusz Kowalewski, Ipsen Japan, July 2023

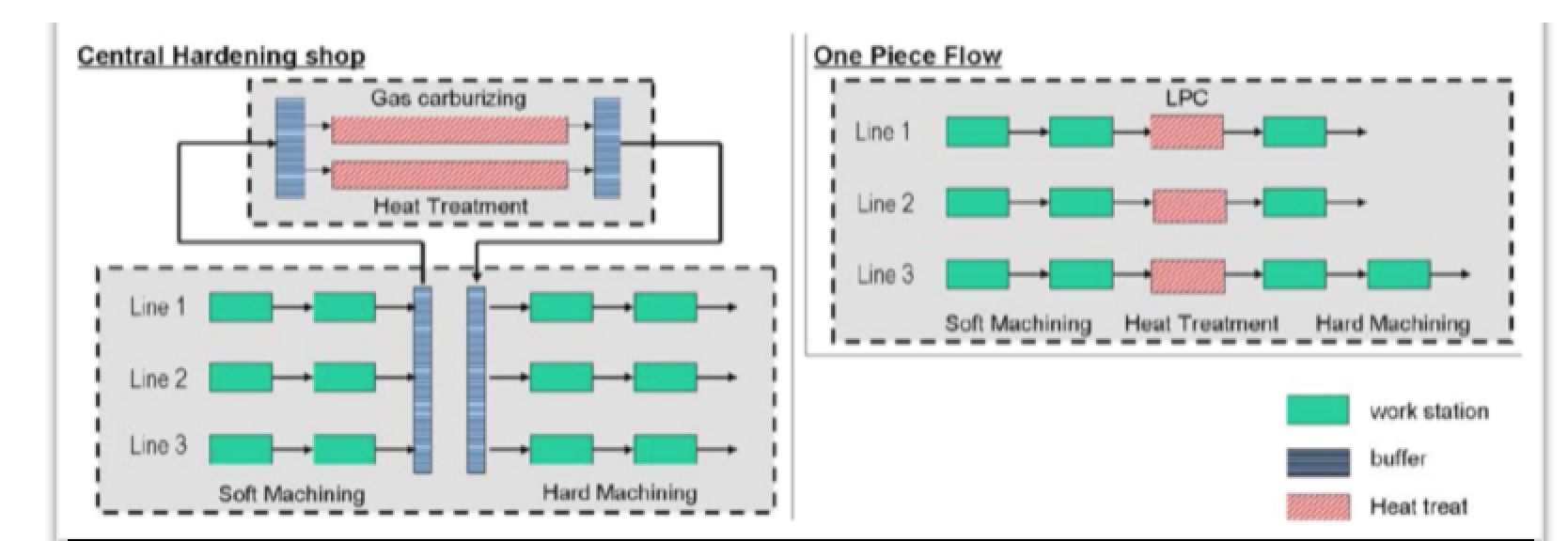

One of these surface modification processes is Low-Pressure Vacuum Carburizing (LPC) for PM/AM parts. LPC is a non-equilibrium process that constantly changes as the carbon concentration levels on a metal surface change. Unlike in an atmosphere carburizing process, LPC’s carbon potential cannot be measured (because it is conducted under a vacuum between 4 to 10 mbar) and set up to achieve a specific carburizing level and case.

LPC is an empirical process that can be designed through computer simulation software. LPC uses the boost-diffusion technique to manage the carbon content and case depth. In the boosting step, the carburizing gas flow must be sufficient to saturate austenite without causing soot deposition or the formation of massive carbides. The software calculates the appropriate gas flow rate for case depth and carbon concentration.

However, PM/AM parts may absorb more carbon due to larger internal surface pores created. The amount of carbon absorbed depends on the metal’s density, the surface layer’s density grade, and whether it is „as machined” or „as sinter/printed.” Enhanced carbon diffusion results in faster case building, especially when the pores are open and interconnected with low-density surfaces.

Janusz Kowalewski, Ipsen Japan, July 2023

As I travel across Asian countries with tropical climates, I have noticed the challenges of operating vacuum furnaces in high temperatures and humidity above 90%. The recent record-breaking temperatures in June have highlighted the difficulties of running a vacuum furnace. Electrical components cannot function effectively in humidity levels above 90%, which leads to a rapid decrease in efficiency. For instance, at temperatures above 40C (104F), VFD efficiency drops by 2% with each additional degree. High temperatures cause changes in electricity flows, which increase resistance. Additionally, excessive humidity reduces transformer insulation and resistance and oxidizes electrical conductors. The difference between cooling water temperature and ambient temperature with high humidity can cause the vacuum vessel to „sweat,” affecting the entire furnace’s electrical system and transformers’ performance. Here are some tips on maintaining vacuum furnaces:

1. Check and tie all electrical connections. Apply conductive copper grease to improve electrical contact between surfaces.

2. Clean all vents in the control cabinet without the air-conditioning unit. Use silica gel to reduce moisture in a control cabinet.

3. Clean the hot zone, check insulation and ceramics, and repair if necessary. Run periodic burnout cycle.

4. Clean the main O-ring and apply a thin silicon vacuum grease or graphite layer.

5. Check the vacuum oil pump condition and change it if contaminated to avoid solidification during prolonged shutdowns. At high temperatures, vacuum oil loses its viscosity and lubrication properties. Replace oil on timely bases.

6. Check all water and gas connections for leaks and clean them to prevent impurities from forming a hard layer and blocking power feedthrough and flowmeters: flush vessel and heat exchanger with Rydlyme solvent.

7. Apply grease to all points per specification, including cooling motor bearings with proper viscosity.

These steps will help ensure the proper functioning of your vacuum furnace and reduce energy consumption.

A vacuum furnace does not cause excessive heat. The hottest part of the vacuum furnace is the diffusion oil pump, compartment, and mechanical pump. To ensure the safety of their employees, Ipsen requires Heat Stress Training, a 40-minute program that covers the symptoms of heat stress, prevention tips, and first aid procedures in case of heat stress. With climate changes and higher temperatures, Heat Stress training is becoming increasingly crucial for the well-being of workers in heat treatment shops as well. Heat stress early symptoms include:

Fatigue

Cramps

Sweating

Dizziness

High pulse rate

Confusion

Nausea

Red, dry skin

Confusion

The best to minimize the possibility of heat hazards such as heat stroke, heat exhaustion, or heat rash is to drink a lot of water, have frequent cool-down breaks, and wear a light-colored cotton uniform.

Janusz Kowalewski, Ipsen Japan, June 2023

Vacuum furnace manufacturers face increasingly complex operational demands due to evolving heat treatment technical requirements and environmental regulations. Vacuum furnace buyers expect more efficient processes, longer component life cycles, and vacuum furnaces with digital control and self-diagnostic capabilities.

The solution to these expectations lies in better mechanical vacuum furnace design and controls utilizing regenerative AI technology. Below are enhancements that have made a vacuum furnace the preferred option for numerous heat treatment processes and applications:

Janusz Kowalewski, Ipsen Japan, May 2023

Exciting new trends in the vacuum furnace domain. I recently discussed with one of the largest automotive manufacturers in Asia how to reduce the environmental impact of their heat treatment operation. Japan will be declared to be Carbon neutral by 2050. The entire country is making a considerable effort to reach its ecological goal. One Japanese innovation is to use Ammonia as a next-generation clean fuel along with Hydrogen because it burns without emitting carbon dioxide. The correlation between part metal, process, and equipment is my starting point for any environmental discussion. You must discuss one factor by taking to account two other factors. You can improve the process, part metal, or equipment alone, but this will not significantly impact cost or reduce CO2 emissions. An example of substantially reducing the environmental footprint would be changing carburizing to carbonitriding. There are several advantages to running carbonitriding operation compared to carburizing. The carbonitrided surface provides better hardenability, wear resistance, shortened process time, resistance to softening during tempering, and lower process temperature. The trimmed process time and lowering temperature reduce CO2 emission. The disadvantage is limited case depths 0.035in or less (0.9mm) ) and poor impact strength. Steels commonly carbonitrided included AISI/SAE 1000, 3000, 4000, and 8600 series with a carbon content of about 0.25%. Higher carbon content in steel will limit the case to 0.012in (0.35mm). The typical process temperature is 1375-1600F (745-871C). The ferritic soft microstructure is converted to a hard martensitic structure after quenching. At the lower temperature range, carbon diffusion occurs too slowly to be economical.

The Low-Pressure Carbonitriding process is carried out in a vacuum furnace under 10 to 80 Torr and controlled by Ipsen Avac-N® software. Vacuum Low-Pressure Carbonitriding provides additional advantages such as:

•no internal oxidation.

•uniform carbonitriding of parts with small holes, even blind holes.

•combination of the carbonitriding process with high-pressure gas-quenching eliminated the need for post-washing.

•low gas consumption of Acetylene C2H2 as the source of Carbon and Ammonia as the source of Nitrogen.

Overall, environmental heat treatment transformation includes:

Ipsen has continued to guide the environmental evolution by providing innovative vacuum heat treatment equipment and processes.

Janusz Kowalewski, Ipsen Japan, May 2023

Duplex coating technology is based on a combination of nitriding and thin film deposited by PVD or PACVD technology (TiN, TiCN, TiAlN, TiB2, etc.). Because the adhesion of the layer on the metal substrate is given only by inter-atomic forces, one of the conditions for its maximization is a metallically clean surface, without oxides, which allows strong bonding between atoms at the layer and nitrided substrate interface, ie between TiN, TiCN and tempered martensite of coated tool.

Thus, the substrate itself is usually in the form of tempered martensite, a supersaturated solid solution of carbon in iron α. However, during nitriding, interstitial nitrogen is also deposited in the lattice, thus creating a doubly supersaturated α´-Fe (N, C) structure, with a nitrogen content of 0.0 – 5.9 wt% and a carbon content according to the chemical composition of the steel and the degree of martensite tempering. For high-alloy HSS steels also with a certain content of cementite and MC, M2C or M6C carbides [1]. By incorporating nitrogen into the α-lattice, the compressive stresses in the nitriding layer increase significantly, on the order of several GPa.

One of the things I’ve learned over time is that tool makers or die casters don’t know, or don’t want to know, that they should be auditing their heat treatment suppliers. And if they already know that, which is based on the CQI-27 application, then they don’t know how to do it.

This is understandable, because the field of heat treatment and material engineering is completely outside the scope of their core business. Either the technology of die-casting or the manufacturing of tools for high pressure die-casting (HPDC).

So how to do it? Here is a rough guide. In order for the audit to fulfil its objectives, it must be comprehensively focused on the entire activity of the heat treatment plant.

Heat treatment plant audit for Nadca 207

As energy costs rise, the importance of furnace consumption rise as well, whether in natural gas or electricity. However, if we are going to buy a refrigerator or a washing machine, we have EU energy label on it showing that the appliance works in class A +++ -.

But what about heat treatment equipment? When investing in new equipment, we usually find out from the offer what the total input of the furnace is, sometimes added information about the input of the cooling turbine or vacuum pumps, input for oil bath heating etc. However, these are the data we need to dimension the cable or circuit breakers and fuses. However, we usually do not receive any information about the actual consumption. And when we ask about it, we usually get strange information from furnace manufacturers, which usually indicates their detachment from reality. At the same time, for example, in a well-managed heat treatment plant, one of the KPI indicators is the sales per 1 KWh of energy consumed, or to calculate the cost of the quotation process, we must know at least the average equipment consumption so we can calculate cycle costs and then set the quoted price.

An integral part of die casting dies manufacturing process is annealing. Its purpose is to relax stresses, caused both by different types of machining and by the actual use of the tool. What does this mean for tool production?

Each insert of dies should go through the following processes:

Drafting drawing Purchase of Material

1. Input material testing (hardening in the oil)

2. Stress relieving after machining (600-650 C)

3. Hardening and 2 or 3 tempering cycles including material testing after quenching

4. Stress relieving after EDM (500-550 C)

5. Pre-heating for welding and stress relieving after welding (500-550 C)

6. Post-oxidation of critical inserts before sampling

7. Stress relieving after sampling (500-550 C) or

8. If nitriding is prescribed, then this process (450-550 ° C)

9. Stress relieving of stresses from thermal fatigue after 1000-2000 shots

10. Stress relieving of stresses from thermal fatigue after 5000-10000 shots

11. Stress relieving of stresses from thermal fatigue after 10000-20000 shots

It can be seen from the above list that annealing processes are of great importance in die making. Only up to step 8 is the tool manufacturer responsible for securing them. However, since the condition for the delivery of the tool according to Nadca 207 is the necessary traceability of all activities, the tool manufacturer must provide all the required documentation for these operations.

Steps 9 to 11 are then up to the user of the tool. However, if during the life of the die it is necessary to perform any additional machining on already hardened parts, e.g. due to shape repair, it is necessary to add even more annealing processes. After milling, EDM, welding, polishing, etc.

Stress relieving processes reducing thermal fatigue stress are shown in Fig. No. 1 at bottom, including their recommended periodicity. This periodicity is approximately consistent with the repeated nitriding processes as recommended by Nitrex for extrusion tools. In both cases, there is a common interest in limiting tensile stresses in the surface layer, promoting crack formation and propagation.

how to perform annealing for die casting dies

In parts I and II, I described the heating phases, the aim of which is to heat up the parts to the austenitization temperature and then to homogenize them well before the quenching itself. These heating phases must take place automatically, without the intervention of the furnace operator, and regardless of the size or shape of the parts.

Similar requirements are for the cooling phase, resp. for quenching, when we need to cool down the parts quickly from the austenitization temperature. This sequence of the processing cycle must also take place automatically, without operator intervention, and regardless of the size or shape of the inserts.

If we have a furnace in which we can control the hardening cycle with Ts and Tc, we have correctly placed load thermocouples Ts and Tc, then the secret of optimal cooling lies in the correct evaluation of these temperatures and in monitoring their temperature difference dT = Ts – Tc. As with heating, it must be taken into account that the hardened steel with temperature above about 500 °C is in a plastic state, below this temperature in an elastic state. Below ≈ 500 °C, we must also take into account the stresses from the temperature difference, and below ≈ 300 °C, the transformation stresses from the change from austenite to martensite are added to this.

At the same time, we must know the CCT diagram for hardened steel so that we can exclude structural phases that reduce the impact strength of quenched and tempered steel. This is mainly an undesirable precipitation of carbides, as well as the proportion of bainite or perlite in the structure. Thus, so we have to control the cooling to miss the area of carbide precipitation for a given steel 1, and at the same time so that we do not enter the area of bainite at all or minimally.2. However, since the carbide or bainite precipitation curves are individual for each steel, the hardening process should be modified with respect to the type of steel being processed – see Figures 1 and 2 for H11 and Dievar steels.

Heating of dies in vacuum furnace part II

Jiří Stanislav, September 2021

Sometime more than 20 years ago, I tried to find a model that I could show to the customer, and which could specify exactly why the shaped insert made by them cracks during hardening. So, we created a hardening model of insert from high alloy steel with a medium thermal conductivity of 30 W/mK, size 600×400 mm, hardened from an austenitizing temperature of 1050 C and cooled to a temperature of 20 C. For modelling was used Deform simulation software. Two cases were studied. The first with a notch in the middle of the bottom of the insert and with a radius R0, the second with the same shape but with a radius R10. The aim of the simulation was to clearly show 1) where the maximum of tensile stresses is and 2) what is the effect of radius size on stress. .

.

Fig. 1 – Computational network for radius R0

Fig. 2 – Computational network for radius R10

The result is shown in Figure 3. As expected, the greatest tensile stress is at the notch. Other tensile stress maxima are on the outer side of the insert, i.e., in places that most designers believe are not significant. The crack in the notch propagates at an angle of about 45 ° as a result of the superposition of tensile stresses in the “x” and “y” directions.

Fig. 3 – Tensile/compressive stress distribution during cooling from the hardening temperature

Fig. 4 – A practical example showing the concordance of a model on a real part made of material 1.2379

In terms of the result, I consider it most important that the model clearly shows that the critical points for hardening are on the outer side of the insert. In the middle of insert, where the designer places the shape of the final product, and which will then be the result of the injection or forming process, there are usually compressive stresses. These are not dangerous in terms of hardening. But it is precisely the cavity of the insert that the designer focuses on, because he wants his product to be exactly as it requested. But that often not enough. It is the outer side of the insert that is the source of danger and critical cracks, and it is up to the designer how to deal with it.

Fig. 5 – Example of a crack due to incorrect mounting of the inlet insert

Fig. 6 – Example of a crack formation from a clamping groove made without a radius

And what is the effect of the radius? Figure 7 shows the tensile stress at the notch for the radius R0, and Figure 8 shows the radius R10. From about 1150 MPa, the tensile stress drops to 780 MPa, i.e., by only 23%.

Fig. 7 – Tensile stress in “y” direction for radius R0

Fig. 8 – Tensile stress in “y” direction for radius R0 R10

So, the basic rule applies. To prevent the parts from cracking, we must eliminate all notches on the outer side of the insert, and at the same time we must apply the maximum possible radius. This is especially true for die casting inserts hardened according to Nadca 207, where we must cool for at least 28 C/min, regardless of stresses and deformation, because we have to achieve the correct internal martensitic structure of the material. It is then up to the designer how to treat these risks. The solution is also a two-step drawing, one for the preparation of the insert for hardening and the second for final shape. Of course, we must not forget about the quality of the material, but that is another chapter.

Jiří Stanislav, June 2021

What is the optimal ratio between hardening and tempering furnaces?

Almost every day I learn from various sources that someone is selling to someone or someone is buying a new vacuum hardening furnace somewhere. However, information rarely appears about how much has been invested in tempering furnaces. So, let’s look at how it works in practice in a commercial heat treatment shop. The typical structure of processed steels is shown in the picture, while the categories of steels for hot work, cold work, HSS or powder steels require at least 2 tempering cycles, but today usually tempering 3, in extreme cases even 4. Together, this is almost 82% of the steel quantity that enters into commercial vacuum heat treatment shops.

Fig. 1 Portfolio of individual types of steels typical for vacuum heat treatment shop

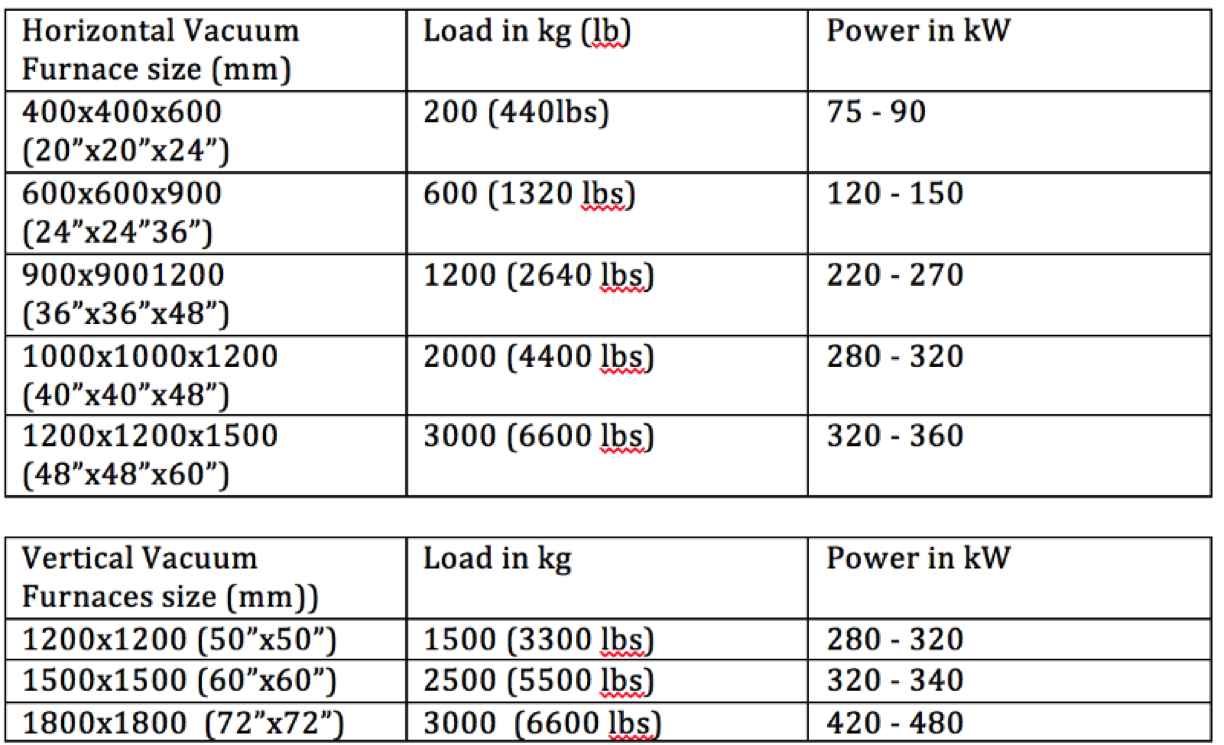

We will make a simple case analysis of the revenues and costs of vacuum heat treatment. The average price for hardening and two tempering on the European market is € 2/kg. The basic dimension of vacuum hardening and tempering furnaces is 600x900x600 mm, furnaces are up to 800 kg. To calculate the costs, we can take the following rates: hardening furnace € 30/h, tempering furnace € 10/ h. In terms of time, if we take into account the usual average batch up to 300 kg, we will fit with each hardening and tempering cycle within about 8 hours.

So, we are able to perform hardening and two tempering cycles within 24 hours. An important condition of this work rhythm is the prescription of the number of tempering cycles and the number of tempering furnaces for this operation. In our case study, we will compare 3 variants. 1) we have a hardening furnace and therefore hardening and two subsequent tempering are performed only in this furnace, 2) we have a hardening furnace and one tempering furnace of the same size, 3) we have one hardening furnace and two tempering furnaces of the same size. We calculate revenues and costs for batches of 100, 200, 300 and 400 kg. The yield is easily calculated, because we multiply the weight of the batch by the price per kg, i.e. 100 x 2 = € 200, 200 x 2 = € 400, 300 x 2 = € 600 and 400 x 2 = € 800.

For costs, we take the basic cost rate for the 100 kg batch, which we increase by an increase in energy and nitrogen consumption by 4% for every 100 kg of charge. The length of each cycle is always 8 hours.

And what is the result?

Variant 1) – we only have a hardening furnace. In this case, we perform tempering in the most expensive equipment, which is also not suitable for tempering with regard to the design of the furnace for high temperature operation, necessary for hardening. Although equipped with convection heating, tempering in a hardening furnace usually does not achieve the same performance as tempering furnaces equipped with a powerful fan for conventional gas heating. It can be seen from Figure No. 2 that even with a load of 400 kg and a price of € 2/kg, we will always harden with a loss. We can say that we will process batches over 500 kg, but the cycle times will be significantly extended and we will not fit into the 24-hour cycle. At the same time, however, we must also take into account the required cooling rates, e.g. according to NADCA, where the furnace should not be loaded above 50% of the permitted weight so that this cooling rate can be achieved (so-called load fill rate).

Fig. 2 Costs and revenues for processing H + 2T in the hardening furnace

Fig. 3 Costs and revenues for H + 2T processing in hardening and tempering furnaces

Variant 2) – we have one hardening furnace and one equivalent tempering furnace. The critical limit becomes a load of about 240 kg. We are already making a profit above this weight. However, sales for this set of furnaces will not be high, because due to the requirement for 2 tempering cycles, the furnaces cannot be used full time.

Variant 3) – one hardening and two tempering furnaces of the same size significantly improve our performance. We get to the profit already at a load of around 220 kg, as it is in the Figure 3. The advantages of this configuration are in time planning, and especially in the utilization of equipment. The hardening furnace can perform 3 hardening cycles per day, so we can effectively harden non-stop, and the two tempering furnaces ensure corresponding tempering cycles, also with maximum utilization of the furnaces. This significantly brings an increase in sales and higher return of investment (ROI). As can be seen from Figure 4, this is a step change, when the theoretical annual turnover rises from 5.7 Mil. CZK for variant 2 to CZK 13.4 million. This is an increase of 235%.

Fig. 4 Costs and revenues for processing H + 2T with one hardening and two tempering furnaces

Fig. 5 Theoretical annual sales for variants 1, 2 and 3

If we compare all variants according to economic aspects, then only for variant 3 we get the payback of the investment under 6 years. In terms of ROI, we have an estimated ranking of 10%, 12% and 23%. Thus, only the variant of one hardening furnace and two tempering furnaces gives us the certainty of good economic parameters of the investment, but above all, good customer service level, meeting the customer’s requirements for pricing, delivery time and quality.

Jiří Stanislav, April 2021

Temper furnace selection and carbon footprint

What should such a tempering furnace look like? There are two basic solutions. Retort furnace and non-retort furnace with direct batch heating. Those who want to purchase equipment only for tempering should know that a furnace with a retort consumes 30% more energy for the same job, ie for tempering, than a furnace without a retort.

If we calculate the service life of the furnace at 20 years, then the retort furnace consumes extra energy during its life, comparable to its acquisition value. But not only that. Because 0.256 kg of CO2 is created per 1 kWh of energy consumed, a huge amount of CO2 is created during the life of the furnace. The calculation is simple. The average hourly input of the tempering furnace with a retort, size 600×900 mm, loading 200 kg, is approximately 25 kW. Cycle time 8h. At 80% annual utilization of the equipment, the consumption is 365 * 24 * 0.80 = 7008 Nh * 25 kW = 175 200 kWh. If I temper in a furnace without a retort, the energy consumption will be 30% lower (see diagram), so I will save 52,560 kWh per year. With an energy price of € 0.20 / kWh, this is an annual saving of € 10 512. In the 20 years of the furnace’s life, it is saving of € 210 240

If we convert this amount to a carbon footprint, then in these 20 years the furnace without retort will reduce the amount of CO2 by 52,560 * 20 * 0.256 = 269,107 kg of CO2. It’s an incredible number. I understand the importance of retort furnaces where diffusion processes are involved. Nitriding, carbonitriding, etc. There is this irreplaceable solution. But if I really only want this device for tempering, then I make a huge mistake and I’m not sure if I’m always aware of it as an investor.

So if we are not very environmentally friendly, and we don’t care how much extra CO2 we produce, we should in all circumstances think about the economic conditions of heat treatment so that the customer gets its value at a good price. And I’m not really sure if everyone really wants it.

Jiří Stanislav, February 2021

Vacuum furnaces are one of the most environmentally friendly equipment within a heat treating shop. But does not mean they are free from safety concerns. For example, the usage of Acetylene (C2H2) and Ammonia (NH3) in vacuum furnaces during the Low-Pressure Carbonitriding may create hazardous conditions. The mixtures of Acetylene and Ammonia in some rare cases may produce Hydrogen Cyanide. Hydrogen Cyanide (HCN), sometimes called Prussic Acid, is an organic compound with the chemical formula HCN. It is a colorless extremely poisonous liquid that boils slightly above room temperature, at 25.6 °C (78.1 °F) When the reactant ratio (Ammonia to Acetylene) is below or above a critical value, the extent of reaction is negligible. But when the critical ratio is correct, high conversions can be obtained generating poisonous gas and creating very hazardous conditions. Also, if there is moisture in the vacuum furnace, Ammonia will react rapidly with copper, zinc and many alloys and corrode them. Double vacuum pumping, Nitrogen purging, vacuum pump gas ballast connected to Nitrogen should be included in process set-ups.

Janusz Kowalewski, January 2021

Vacuum furnace hot zone life depends on the process requirements. Some processes are harder on the insulation than others. The below 8 procedures can help extend hot zone life:

1. Keep leak-free. Check your leak-up rates weekly. 2. Do burn-out cycles on a regular basis. This should be a recipe that goes at least 100F over your typical process temperature. 3. Keep the furnace clean! Metal debris can easily burn into the heating elements and insulation during heating causing premature damage to the graphite. 4. Clean/dry your process parts. Excess oil or cleaning fluids can cause poor pump downs and add to graphite insulation deterioration. 5. Keep cooling gas pressure at minimum required by material and parts thickness. Try step-down quenches, high pressure for the first few minutes then drop the pressure down for the remaining cool. 6. Load gently. Checking all the heating element hardware for tightness/breakage along with checking for loose insulation retaining pins. 7. Make sure bungs and nozzles are restriction free. If there are restrictions, then a quench gas will be forced to go behind the insulation breaking it and blowing retaining pins. 8. Keep the vacuum in level to avoid alloy sublimation.

Janusz Kowalewski, January 2021

Cooling speeds and uniformity are some of the most important operating features in vacuum furnaces. Metallurgical, mechanical, and distortion of the entire load and individual parts will depend on effective and uniform heat transfers during the cooling segment. The inherent gas flow’s instability in vacuum furnaces can lead to non-uniform hardness, excessive distortion, and a mixture of metallurgical structure within the part and the load. Load configuration, parts spacing, cooling gas pressure, gas type (Nitrogen, Argon, Helium, Hydrogen), gas velocity, gas flow pattern, fan wheel design, heat exchanger design, cooling nozzle shape, and size and locations (bung designs in a square hot zone) impact cooling speeds and uniformity. One of the least discussed and understood parts are the cooling nozzles. The nozzle design, spacing between the nozzles, and the nozzle locations have an impact on the speed and cooling uniformity. Several cooling studies have shown that increasing the number of nozzles beyond the optimum number has a diminishing impact on cooling speed.

Janusz Kowalewski, December 2020

Some vacuum furnaces are used for very harsh and highly contaminating processes. One of the processes performed in a special design vacuum furnace in this category is chromium purification. The process is brutal on vacuum furnace components such as graphite insulation, ceramic, heating elements, and vacuum pump systems. The process has three stages: bidder burnout, purification, and furnace cleaning. Bidder burnout: When the furnace reaches temperature 1550°F (843°C) most bidders is taking out from chromium briquettes and pumping out from the furnace. Purification: At around 2000°F (1093°C) the carbon and oxygen start to react and combine and create carbon dioxide and carbon monoxide. This is where the purification happens and the gases are driven out of the chromium. The soaking temperature of 2300°F (1260°C) is where the carbon and oxygen reaction is most effective. The soaking lasts several hours. After the purification, cleaning process starts, chromium molecules are removed from graphite insulation and heating elements. Predictive maintenance and frequent burnout cycle at 2400°F (1320°C) is highly recommended. Monitoring the vacuum level timing is the best guideline for the burnout frequency.

Janusz Kowalewski, December 2020

The vacuum furnace industry is diversified with 6 countries dominating the vacuum furnace industry. But if you look for innovation the number of countries shrinking to mercy 3 countries provides most (but not all) innovations. Some of the past decades were instrumental in vacuum furnace advancement. In the 1970’s we saw the first development of High Pressure Quench in vacuum furnaces. Credit should go to a French company (today not existing) for the introduction of 2/3 bar pressure quench followed by Ipsen introduction of 5 bar pressure. 1990’s industry developed new insulation, implemented LPC using acetylene on mass scale, credit should go to Moscow Lomonosov University, JC Hays Japan (today IHI Group) and Ipsen. For the list of innovations in the vacuum furnaces please scroll down.

Janusz Kowalewski, December 2020

Heat Treatment and Additive Manufacturing

Some AM parts require vacuum heat treatment. Below are suggestions how to enhance AM techniques to optimize heat treatment: 1. Increase the load density. Optimize available surface space to have as many parts on a single plate as possible. 2.AD parts’ thin walls dictate the loading position’s support and fixtures design. Loading should be designed in vertical positions with the help of minimum numbers supporters. 3.Relatively low wall thickness increases the efficiency of heating up but also creates challenges. Setting up cycle parameters such as heat up rate and cooling speed should be very precise so it will not adversely affect the parts. 4.Loading techniques for parts with high and thin walls. Components should be loaded vertically (in same cases under an angle) with 10 mm spacing between parts. 5.The vacuum furnace for alloy materials such as Titanium, Nickel, Cobalt, Tungsten, and Cobalt-Chrome-Molybdenum metal hot zones are recommended. For high-temperature applications above 1400°C Tungsten could be used. For tool steel, graphite hot zones are acceptable. 6.The furnace should have the capability to cool by different gases according to the alloy requirements.

Janusz Kowalewski, October 2020

Before Purchasing a Vacuum Furnace

To be competitive in the market, manufacturers should consider true vacuum furnace ROI before making the final decision. With many solutions available, it’s important to calculate a vacuum furnace’s true ROI before making a purchase. While many solutions are appealing because of the price, investing in high-performance vacuum furnaces can ultimately facilitate a better, more profitable solution for your business. Oftentimes an ROI analysis only focuses on furnace price; however, there are a number of technical and service related features you should examine in-depth in order to determine a vacuum furnace’s true value. It is important to remember warranty is not insurance against furnace breakdowns. Free parts replacement does not make up the cost of lost productivity. The ability to use the furnace without breakdowns is more valuable that free part replacement. ROI evaluation: 1. Operating cost, 2. Maintenance and Repair Interval, 3. Parts Replacement Frequency and Reliability, 4. Service and Spare Parts Delivery Time.

Janusz Kowalewski, October 2020

2021 HEAT TREATMENT MARKET TRENDS

How to Shorten a New Furnace Installation

Many customers are asking how they can shorten a new vacuum furnace start-up. Some customers are choosing to install their own furnaces themselves and only start-up and training rely on OEMs. Here is the short list of preparation: 1.Make sure the floor level is leveled correctly. Level and anchor vacuum furnace and pumps. 2.Flush gas piping and buffer tank with nitrogen before connecting to furnace, then pressurized and check for leaks. 3. Connect and check the water and air systems for leaks and pressure. 4. Remove protection coating from flanges, clean grooves and O-rings with ethylene alcohol and grease it with silicon. 5.Check EMF interference. 6.Make sure all electrical wires on the furnace are securely connected and motors are rotating correctly and have correct voltage.7. Check wiring in the control cabinet for solid connection. 8. Make sure electrical components are set for a correct voltage 120/220V.

to be continued…

Janusz Kowalewski, September 2020

Graphite or Metal Hot Zone?

We all love graphite insulation in hot zone and heating elements in the vacuum furnaces. Industry is selling more graphite type furnaces that all metal hot zone, but that not mean all metal type furnaces doesn’t have advantages and in many cases necessities for some processes and material. Graphite material is easy to work with, come in variety of style, purity, thermal conductivities. What you are looking as furnace designer is dimensional stability, smooth surface, low ash content and low and uniform thermal conductivity through entire insulation sheets. Graphite is hygroscopic material and is prone to absorb water from air causing outgassing and slowing the pumping time. Surface graph foils or inner foils sheets minimize water absorption and then outgassing. All metal hot zones offers higher vacuum level, faster heating, pumping, and quenching (limited gas cooling pressure). All metal hot zone requires higher heating power in the long run because of increases heat losses due to shielding contamination. With proper shielding distancing and spacing, polishing first shield surface and proper maintenance all metal hot zone may reach near graphite insulation efficiency. Materials and processes sensitive to even smallest traces of oxygen requires metal hot zones.

Janusz Kowalewski, September 2020

Future of Warranty

In the US, the average warranty cost in all warrantable equipment is 1.4%. In the heat treatment industry, warranty is an integral part of what we do. How we handle and respond to warranty claims differential vacuum furnace manufacturers into best, good and ugly categories. The rapid heating/cooling pressure changes, corrosive/harmful evaporation, oxidation, and contamination characterizing vacuum furnace operations are imposing on internal parts stresses, degradations and eventual parts failures. Constant cycling of furnace conditions create engineering dilemma for designers to choose correct design/material and how to monitor the part performance. Here is the good news: Vacuum furnace is assembled from around 450 identifiable parts (some parts are in numbers) and critical parts could be traced, recorded and analyzed.

Janusz Kowalewski, September 2020

OPTIMAL HEAT TREATMENT OF HOT WORK STEELS FOR DIE CASTING

The heat treatment of hot work steels for die casting is vacuum heat treatment application which requires a special attention. The final mechanical properties are influenced by many parameters related to the steel selection, manufacturing process, heat treatment and in special cases to the surface modification. The inseparable parts of problem are testing methods. The paper deals with principles which should be used in standard praxis which non-compliance results in low tool life or legal problems in supplier-customer relationships.

Heat treatment of hot work steels is one of the most demanding disciplines in the field. Not only in terms of its own procedures, but above all in terms of determining and adhering to process parameters to achieve optimum service life result with important variability in heat-treated parts. However, when selecting process parameters, it is always necessary to take into account what procedures are ordered and what procedures are usual.

And there is a contradiction between the tool manufacturer’s requirement for tool life and the ordered or usual routing. It is a paradox that the client does not have the usual procedures, or has no knowledge of them, on the other hand, this is what the client requires from heat treatment supplier.

Of course, the next comprehensive chapter is tool design, material selection and hardness, or the way the tool is used in production, but in this article, we will assume that this customer has already investigated and aligned with the usual routings and the best praxis.

Although the group of hot work steels is extensive, basically the same input control is required to all grade of steels. Its definition is implemented in NADCA-207, rev. 2016 [1]. While this definition is primarily intended for die casting molds, it can generally be applied to other applications such as forging dies, extrusion dies, the tools for rolling or hot pressing.

From the point of view of initial testing, the control of chemical composition is a basic, but not decisive, condition. The resulting mechanical properties are determined primarily by the micro-purity, grain size, amount and distribution of primary carbides. From this point of view, in order to distinguish precisely these effects, the usual procedure is to examine the input quality of the material by impact tests measuring the toughness.

It has been shown that the higher toughness of the material is affecting higher resistance of the material to thermal fatigue cracking. A higher impact strength value can also positively affect the formation of macro-cracks associated with tensile stresses.

Impact tests are performed on samples ideally quenched under oil cooling conditions and the measured values should reach the values defined by NADCA-207, rev. 2016 (Tab. 2). If the predicted values are not reached, it is the responsibility of the material supplier to replace the supplied material with a material that would provide the required parameters.

Impact tests are carried out on samples with the least suitable fiber direction to ensure that the limit mechanical properties of the material are evaluated.

3. Heat treatment

The heat treatment of these steels should be carried out according to generally known, conventional procedures. The question is what is meant by these usual procedures. There are no Czech standards for most modern steels, only steel supplier’s material sheets exist. The exception is NADCA-207, rev. 2016 [1], but it is only a recommendation for members of the Association of die casting in the USA.

A properly conducted heat treatment process should ensure that the expected mechanical properties of the input material are achieved. Leaving aside the possible problems with deformation during heating, the most important phases of heat treatment are austenitizing and cooling.

The austenitizing should ensure, on the one hand, the correct dissolution of carbon in the matrix, the partial dissolution of carbides, but on the other hand, it should not allow an excessive growing of the austenitic grain compared to the initial state. These two requirements are contradictory and it is necessary to choose a compromise solution linked to the austenitizing time and temperature, and considering that we heat the 3D body in a heterogeneous vacuum furnace environment.

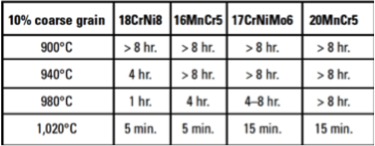

If heat treatment according to the NADCA-207 specification is not required, the temperatures determined by the steel manufacturer are considered as normal temperatures (green field). If the heat treatment is required in the conformity to NADCA-207, then these temperatures are within the allowed NADCA-207 range (orange field), usually at its lower limit (Table 3).

Higher austenitizing temperatures provide better solubility of the primary carbides, but these carbides precipitate during cooling (quenching in a gas stream) along grain boundaries and reduce the resulting toughness of the material. Paradoxically, due to the higher solubility of carbides, higher austenitizing temperature means higher resistance to self-tempering during use of steel at the working temperature of the tool (Fig.1), greater resistance to thermal fatigue cracks, but at the same time a great risk of grain growth with corresponding lower toughness.

In addition to the temperature and the austenitizing time, a cooling rate is also important, which reduces the possibility of precipitation of these carbides. Higher temperature also reduces Ms and increases the amount of residual austenite in the matrix due to more enriched austenite. This residual austenite is then transformed into not tempered martensite, which reduces toughness.

The second most important parameter of austenitizing is the time. The holding time at the austenitizing temperature must be sufficient to homogenize the austenite, while also partially dissolving the carbides, but it must not allow excessive, uncontrolled growth of the austenitic grain. The higher the temperature, the shorter austenitizing time should be. In case the usual heat treatment is required, it is necessary to follow the instructions of the steel producers. In the case of the NADCA-207 heat treatment, the austenitizing time is the time prescribed as 30 minutes from the complete warming of the part to the end of the dwell under the following conditions (Fig. 2):

Ts (Surface) = Tp (Programmed) and at the same time Ts (Surface) -Tc (Core) < 14 C

If the furnace is not equipped with a temperature measurement by 2 load thermocouples Ts and Tc, the maximum holding time at the austenitizing temperature is limited to 90 minutes from point when Ts = Tp

In order for this parameter to be objective and controllable, the location of the thermocouples must be defined in addition to the above conditions. The tool manufacturer is responsible for making the correct holes for Ts and Tc thermocouples. (Fig. 3).

A very important parameter of the process control is the cooling rate in the area between the austenitizing temperature and reaching a temperature of about 400-450 °C. This should be a controlled parameter with a minimum speed of 28 ° C / min. Only under this condition can the carbide precipitation area be missed for H11 (1.2343) and H13 (1.2344) materials, meaning deterioration of impact toughness of the material (Fig. 4).

The temperature range between the austenitizing temperature and about 500 °C is not dangerous for the formation of cracks, the material is still plastic in this temperature range. Below 500 °C, however, it becomes solid and the material is subject to stress due to the temperature difference between Ts and Tc. This is the reason for applying the isothermal period.

In order for the material to survive this high cooling rate without cracks and extreme deformations, it is necessary that its shape be adapted to this objective. More important for the further development of the service life, more than deformation, the structural properties of the material are achieved by heat treatment. Carbide precipitation and extreme austenitic grain size growth are one of the basic sources of failure. In some cases, extreme grain growth may also be due to the inhomogeneity of the raw material.

All parts for high speed cooling must be designed with minimum radius R3-5 mm on all critical shapes, surface roughness must be treated after machining, and no notches must be created to concentrate stress. Thus, it is on tool manufacturer to prepare its parts with correct design so that they can undergo a high-speed cooling process, regardless of deformation. Otherwise, any exception to this rule can cause and usually lead to a deterioration of the mechanical properties of the steel. It should also be noted that the greatest tensile stresses leading to large cracks are on the perimeter of the mold, not in the shape that creates the product itself

The cooling rate is not usually prescribed, and the choice is therefore up to the heat treatment supplier except when the heat treatment is ordered by NADCA-207. Since this parameter is not generally mentioned on the material sheets, it is very difficult to speak about the usual parameter. Therefore, in order to make a clear distinction as to whether this parameter was chosen appropriately or not, a more objective evaluation of the heat treatment by means of impact tests must be carried out.

After hardening, the material must be tempered at least twice. Despite all efforts to complete the martensitic transformation, the material still contains a large amount of residual austenite. Firstly, it is given by the position Mf and secondly because it is a 3D body with heterogeneous temperature distribution inside. When the surface is cooled to 70°C, inside the body even more than 50% of the residual austenite may be present. The question is therefore when to start the first tempering when the transformation of austenite to martensite is not yet complete.

The usual method states that as soon as possible after quenching, once the part reaches a surface temperature of 50 -70°C. The problem, however, is that during cooling at low temperature, the greatest risk of cracking is due to the fact that we are below Ms and there is a superposition of stresses from both temperature difference and phase transformation. Therefore, the gas cooling in the furnace is usually applied until Tc = 150°C (some steel manufacturers recommend cooling in the furnace up to Tc =100°C), then only in free air. Time to reach Ts = 50°C is then attached to the weight and die shape and can be much longer than “as soon s possible”.

Therefore, the definition of time to first tempering is an abstract concept and cannot be considered as a predefined parameter. However, after quenching the surface temperature must be controlled even after the part has been removed from the furnace. For this reason, a magnetically clamped (usually bimetal) thermometer is placed on the parts and the surface temperature of the part is measured while cooling off the furnace. There is (usually) no record of this phase of the process.

After reaching the surface temperature Ts = 50°C the first tempering can be started. However, this period can take several hours for large tools. Also, the view of this temperature Ts = 50 °C is different between NADCA-207 and some steel producers. For this reason, the usual procedure will vary according to the client specification and may also vary according to the type of material used.

The tempering must be carried out at least twice, taking into account the not tempered martensite resulting from the transformation of residual austenite after the first tempering. For more demanding applications, however, it is better to temper all of the structural components at least twice and therefore triple tempering is needed.

As important is the input control of the purchased material to avoid future disputes, so is the output control after heat treatment. The check is again carried out by impact tests on a sample of the material, which goes along with the real part through the entire heat treatment process. In case the impact tests do not reach the usual toughness values after the heat treatment, the heat treatment supplier is obliged to carry out a corrective heat treatment. It is generally agreed that only one repair heat treatment is allowed. However, it is necessary to apply soft annealing before corrective process. The annealing conditions result either from the steel supplier’s prescription or from NADCA-207 specification, if any.

In the event that even a corrective heat treatment does not give adequate results and the material input tests are OK, the heat treatment provider should be obliged to cover all costs incurred so far.

Only the evaluation of the heat treatment result by hardness measurement is absolutely inadequate. It is known that all types of structures (martensite, bainite, mix perlite/bainite) after heat treatment may under certain circumstances have the same hardness. But only some of them correct toughness.

In case that after the quenching and tempering the hardness is higher than the specified one, then it is suitable to include the 4th or further tempering to get the required hardness. It is assumed that the tool maker has strictly substantiated reasons for the determination of such hardness and the supplier of heat treatment is not obliged to examine these reasons.

However, if the hardness after heat treatment is lower than the ordered one, then it is not possible to make an optimal decision without knowing the impact toughness. Since lower hardness means higher toughness, it is usually more reliable to release the material into use than to rework it. However, the criterion which this process can decide is only in the impact tests. Therefore, if the customer does not perform these impact tests as a usual method of testing, then it cannot be expected that it could be successful in disputes concerning the complaint of heat treatment.

The cryogenic treatment of hot work steels has so far been mainly applied to forging tools. The sub-zero process is usually initiated immediately after quenching so that the temperature drops below Mf and allows the phase transformation to be completed. Further temperature decreasing not only completes the transformation of residual austenite but also supports the secondary carbides precipitation improving wear resistance.

No significant changes in toughness were found, but a significant improvement in the abrasive properties of the material was found. Therefore, this aftercooling method is more common in forging tools than in die casting tools. NADCA-207, rev. 2016 does not yet know this process and there is no obligation to apply it to NADCA-207 heat treatment.

The optimal heat treatment of hot work steels is only with the task, not to impair the initial material properties. But by no means heat treaters can improve them. In case the application requires different, specific properties, they can be solved by further subsequent surface treatments. These are either nitriding, PVD or CVD layers or a combination of both, the so-called duplex coatings.

These nitriding or duplex coatings bring improvements in those cases where it is necessary to change the amplitude of the tensile stresses to compressive or to prevent increased wear or diffusion of the formed or cast material into the steel. Coatings are also important when it is necessary to prevent the material being processed from interacting with the tool material. In the case of die casting molds, it is mainly soldering, ie. the interaction of the tool surface and aluminum.

Processes for better run-in properties of the die material have also been successfully developed. E.g. controlled oxidation at die casting molds produces good results. Its advantage is to improve the uniformity of lubricant dispersion during the running period and thus better surface cooling with lower abrasive effect. The aim is to avoid direct contact of the aluminum with the steel surface at the start of operation when the mold is not yet blown and tends to initiate micro-volume centers for soldering and thermal fatigue cracks.

Heat treatment is qualified as a special process whose parameters have many variables. These parameters have not only a technical aspect related to the feasibility of the process, but also the usual parameters that affect the legal aspect of the case. Despite a significant improvement in awareness of this problem, it can be stated that continuous economic pressure on tool manufacturers leads to omit basic, even routine operations such as material input testing and testing after heat treatment, and at that moment the legal aspect of the matter becomes difficult to justify.

Jiří Stanislav JST Consultancy, Elišky Krásnohorské 965, 46014 Liberec 14, stanislav.jirka@gmail.com

Literature

[1] Nadca-207, Rev. 2016, Publication 229 – Special Quality Die, Steel and Heat Treatment, Acceptance Criteria for Die Casting Dies

[2] Johnny Sjostrom – Chromium martensitic hot-work steels – damage, performance, microstructure, Karlstad University Studies, 2004:52

[3] Corwyn Berger – Extended tool life on die casting, Presentation Brno, 1999

[4] Šuchman, Lataš, Ciski, Graf – Kryogenische Behandlung als Verfahren zur Erhohung der Standzeit von Schmiedegesenken, Project Eureka

[5] GM Powertrain Group, DC_9999_Rev18

Amazing Vacuum Furnaces

Ion Vapor Deposited Coatings – Improved Corrosion Protection for Additive Manufacturing

Abstract

This paper will discuss applications of highly adherent, continuous aluminum coating onto metallic parts using Ion Vapor Deposition (IVD) techniques. Ion vapor deposition improves corrosion resistance for parts exposed to harsh environments such as salt water or high temperature jet engine gases. The IVD coating is soft and ductile with properties virtually identical to those of pure aluminum. Extensively tested in laboratories and service environments, IVD coating improves parts performance, and at the same time is environmentally friendly, corrosion resistant and replaces the need for a cadmium coating.

The unique IVD equipment remains one of the most economical means for production coating with aluminum. It provides a uniform, dense and adherent coating, which is not limited to line of sight application. An aluminum coating applied by the IVD offers the following advantages:

Aluminum Ion Vapor Deposition applies for marine, aerospace and defense industries for parts exposed to harsh, corrosive environments. The use of vacuum deposition techniques as a method of coating down metallic layer on both metal and super alloys is well developed. This paper details decades of experience of using the ion vapor deposition process and experience producing full-scale production equipment.

Introduction

Background

One of the growing methods to eliminate surface imperfection and improve metal corrosion is aluminum ion vapor deposition. IVD is a physical process for applying pure aluminum coatings to various parts, for corrosion protection and improved surface quality. The IVD process is designed for handling large volumes of small parts or few large parts – as large as 40 inches wide and 140 inches long.

IVD technology proves itself on a variety of metal and super alloy parts exposed to highly corrosive surroundings. Aluminum evaporation improves aluminum surface adhesion and purity without limiting coating thickness. The coating meets the requirements specified in MIL-C-81706 for electrical contact resistance of aluminum alloy panels. The corrosion resistance performance equals to various cadmium coating with the conclusion that IVD aluminum can replace all cadmium coatings without exception. Preliminary testing on additive manufactured (AM) parts provides similar contact resistance and corrosive resistance achieved on parts made by casting or milling technologies.

The major components of the IVD system are:

The IVD Process

Ion vapor deposition is a process for applying pure aluminum coatings to various substrates and the parts, used mainly for corrosion protection. The process is applied in a vacuum vessel of various sizes, called an Ivadizer®. To prevent contamination of the pure aluminum coating from oxygen and water vapor in the atmosphere, the aluminum coating is applied to the substrates in a vacuum. The vacuum vessel is evacuated to a 10-5 Torr range pressure to purge the system prior to backfilling with Argon to 2×10-2 Torr.

At this pressure, the parts are subjected to an ion discharge cleaning operation. A high negative potential is applied between parts, being coated and the evaporation source. The Argon gas in the chamber ionizes and creates a glow discharge around parts bombarding them with positively charged ions. Bombarding the part’s surface effects a cleaning operation prior to coating. By also using a vacuum, the boiling point of aluminum is decreased from its atmospheric boiling point.

In this process the substrate, or part being aluminum coated, is the cathode of a high voltage system. A negative potential of 500 to 1500 volts DC is applied to the part. Aluminum is evaporated from resistively heated elements or from an aluminum slug by electron beam evaporation. Specifically, aluminum alloy wire is fed into a resistively heated source called a boat in the IVD aluminum coater.

The boat is made from a special composite material that has the proper electrical characteristics to get sufficiently hot with current flowing through it, yet not erode rapidly or create hot spots. The boat also has sufficient strength to withstand stresses imposed on it at operating temperature. The aluminum is evaporated under vacuum condition from the boat in a process similar to water boiling or evaporating out of a pan.

The vaporized aluminum, a gas, spreads out into the vacuum vessel coating the part and the shell of the vacuum vessel near the boat. The hot aluminum vapors condense to form an aluminum coating on the parts in exactly the same manner that water would condense on a metal plate held above a pan of boiling water.

A part placed above the evaporating aluminum becomes hot. A heated part is primarily due to the heat of condensation that develops whenever a gas, water or aluminum, changes state(s) from a gas to liquid or water, or from a vapor (gas) to liquid to solid, for aluminum. In the case of aluminum coating, parts are also heated from radiation off of the hot boat.

IVD aluminum coatings offer several process advantages to mitigate surface imperfections. IVD aluminum can be used up to 925°F. IVD aluminum can be used on titanium without creating solid metal embrittlement concerns. IVD aluminum can be used for space applications. When needed, IVD aluminum coatings can be polished to a mirror-like finish.

Tests have also shown that an IVD aluminum coating is superior to cadmium and tin-plating in electromagnetic interference uses. Depending on the application, IVD aluminum coatings are applied in the range of 0.0003 to 0.002-inch thicknesses. When the coating cycle starts, the IVD operator addresses a menu to input the operating parameter to coat the parts. The menu is retained for future use for similar parts. Pump-down, glow discharge cleaning, IVD aluminum coating, part cooling (when required), and venting the coater to atmospheric pressure is automated.

The largest use of IVD aluminum is for corrosion protection of ferrous alloy parts. The aluminum-coating process can be used on all small parts such as building materials, fasters and housings, screw assemblies, blower impellers, etc. However, there are also applications for non-ferrous parts coated for dissimilar metal protections, such as copper-alloy bushings.

Applications

IVD is adaptable for coating thickness needs. Typically, IVD aluminum coatings are applied in the range of 0.0003 to 0.002 inch in thickness. Coating thickness requirements do not apply to contact points, recesses, internal threads, and other areas where a controlled deposit cannot be obtained, such as in corners of parts and in radius of intersecting surfaces.

Table 1. Coating thickness classifications.

Specifying a Class 1 coating ensures that hard-to-coat areas on complex-shaped parts get adequate coverage and coating thickness. Most Class 1 coatings are typically in the 0.001 to 0.0018 inch thick range. As noted in Table 1, Class 1 coatings are used when dimensional tolerances are not a concern and where maximum corrosion resistance is needed. The increase in total cycle time to applies to a Class 1, 0.001-inch thick minimum coating versus a 0.0005-inch thick coating, which is small. Where maximum corrosion resistance is needed, a thicker coating can be applied very economically. A thicker coating also has an advantage for complex-shaped parts.

Class 2 coatings are used for additional corrosion protection, but where Class 1 coatings cannot be used because of dimensional tolerances. Class 1 and 2 coatings are also used for dissimilar metal compatibility.

Class 3 aluminum coatings are used for corrosion protection and/or dissimilar metal compatibility. Class 3 IVD aluminum coatings, 0.0003 to 0.0005 inch thick, are applied to threaded or other close-tolerance parts for corrosion protection and/or dissimilar metal compatibility. Typically, Class 3 coatings are applied on fasteners or for other close-tolerance applications where thicker coatings would exceed dimensional tolerances.

Corrosion Protection

IVD aluminum provides excellent sacrificial corrosion protection on various metals and super alloys parts used by aerospace and marine applications, and manufactured by traditional and additive manufacturing methods. IVD has been particularly successful on fatigue-critical aluminum structure providing corrosion protection. Those applications include various large wing sections and bullheads used on military and commercial aircrafts. The IVD coated panels in Table 2 were submitted for neutral salt fog test as specified in MIL-DTL-83488.

Table 2. Natural salt fog resistance for each class

The bars in Table 2 show the corrosion resistance of IVD aluminum parts from chromate conversion coated and tested to failure (red rust). This study encompasses about 900 data points for 4130 steel test panels representing hand-fixtured details and for alloy steel NAS 584 fasteners details. There are 148 data points for Class 1 coatings, 167 for Class 2, and 56 for Class 3 for the test panels. There are 13 data points for Class 1, 237 data points for Class 2, and 284 data points for Class 3 for the test fasteners.

The data in the graph shows a good margin of safety for corrosion protection of coated parts versus minimum specification requirements for Type II aluminum coatings, shown in Table 3 below.

Table 3. Exposure times for corrosion resistance tests in a neutral salt spray test per ASTM B-117.

One of the largest areas of application is coating high-volume titanium fasteners. The table below presents coating uniformity on a fastener.

Conclusion

The use of ion vapor deposited aluminum produces a pristine, environmentally friendly and safe finishing system on complex parts. The versatile process is widely used in additive and subtractive manufacturing settings.

Janusz Kowalewski

Ipsen, Cherry Valley, Illinois, USA

Janusz.kowalewski@ipsenusa.com

Vacuum Heat Treatment for Aerospace

In the age of Artificial Intelligence (AI) the vacuum heat treatment process is define as a group of metalworking processes design and control by predictive and prescriptive tools such as machine learning, to alter the physical, and chemical properties of a material in order to manipulate properties such as hardness, strength, toughness, ductility and elasticity without human intervention during manufacturing process.

Vacuum processes including brazing are usually a high temperature (typically 1500°F/815°C – 2250°F/1232°C). There are several advantages to heat treat under vacuum conditions:

The Artificial Intelligence in aerospace manufacturing can be applied to vacuum heat treatment resulting in increase in furnace reliability, elimination of rework after heat treatment, and increased furnace efficiency. In order to increase the efficiency of the vacuum heat treatment process, furnaces should be integrated into the production flow of the manufacturing process. Integration is only possible if the control system of the furnace has communication capability with the facility ERP (Enterprise Resource Planning) and CMMS (Computer Maintenance Management System). The goal is to simplify vacuum furnace operation and at the same time increase the reliability and efficiency of the furnace. The control system should have the following capabilities:

Vacuum furnace operations changed drastically in the last 5 years. The next task is design furnaces capable of automatic reasoning during the heat treatment cycle and provide solutions to furnace performance problems. Current development in the control system with PLC/Computer allows instantaneous communication with company production software. PLC/Computer base controls are designed to analyze furnace performance by monitoring all critical components such as vacuum pumps, valves, SCR, contactors, actuators, safety switches, heating elements, water flows, etc. Sensors monitor such parameters as motor vibration, motor temperature, motor’s electric power characteristic, water flow and temperature and heating element resistance. Routine data is available through Internet. Data indicating parameters outside of acceptable norm triggers an email or massage notification.

Easy- to- follow programming allows the operator to choose a recipe from the pre-stored standard cycles for a specific product. The core of Artificial Intelligence manufacturing is to convey information to decision makers both simply and visually to make it easy to recognize abnormal conditions that result in waste. Light, horn, and computer messages on the HMI inform decision makers of any abnormal situation within the vacuum furnace.